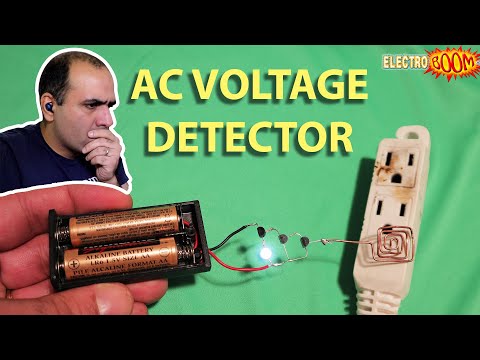

Hi, this is Wayne again with a topic “Weekend Projects – Non-Contact Voltage Detector”.

Hi, i’m david with make most makers know what a multimeter is and how they operate, but have you ever wondered about those non-contact voltage detectors similar to the pen-like devices electricians use to test the outlets in your walls today we’re going to build a diy version of That tool, however, this project is only for learning about electricity, never use it for working on any power sources, especially your home’s ac power. This project only requires a few electrical components, many of which you can pick up at your local radio shack or you may already have at your workbench. You’Ll, also need a few basic tools. The circuit operates using multiple transistors. You can think of them like switches, each controlling the next switch in the circuit.

Another feature of transistors is that they can act as amplifiers. So if you attach the output of multiple transistors together, you can increase their gain. This gain is what we will use to light. The led on the enclosure which indicates a nearby wire is live with voltage.

Just a slight amount of voltage, even that created by induction or static charge, is enough to trigger the transistors. Okay, let’s get started start by trimming down the perf board, so it’s 15 holes wide and seven holes tall also trim off the corners of the perf board, so the enclosure lid will fit properly. Transistors have three leads and each perform different functions electronically. This determines how they are installed in a circuit place, a transistor on your work surface, with the flat side facing up the leads from left to right are the emitter the base and the collector insert and solder the three transistors into the perf board.

According to the schematic be sure to pay attention to their orientation, you can find the schematic additional pictures and useful tips and tricks on the project website. Now it’s time for some clever connections using the transistor leads bend. The transistor leads. So the third emitter is touching.

The second base and the second emitter is touching the first base double check to ensure you’ve bent the correct, leads and solder. Then the first is emitter and the third transistor is base, so they extend away from the previously bent leads solder, all the transistor connections. According to the project, schematic solder in the three resistors be sure to check their resistance before you solder. All three have different resistances again refer to the schematic for proper placement, now cut two lengths of wire and strip the insulation from the ends.

You’Ll need to trim down the leads on the led and solder those wires to the led use a little bit of heat shrink to protect the circuit from shorts solder. The led wires to the perf board follow the same procedure for preparing the switch once completed. You’Ll solder, the switch to the battery clip and the remaining two wires to the perf board according to the circuit diagram, the last connection is the wire that will be attached to the external copper pad used for sensing electric fields solder it in place connecting it to The outer transistor base now it’s time to work on the enclosure start by drilling two holes in the cover, one for the led holder and one for the momentary push button switch once drilled. Add the two components and the cover is done.

Next cut a piece of copper-clad pcb material with a rotary tool or hacksaw blade and attach it to the enclosure with a piece of double-sided tape, carefully drill, a hole through the center of the copper pcb and plastic case once completed feed the extra wire from the Perf board, through the hole and solder it to the copper pad. The last step is to insert the perf board and battery into the enclosure and screw the lid on. That’S it.

Let’S give it a test to use the non-contact voltage detector place it near a live ac power line and depress the button. The led will light up when it detects even the slightest amount of voltage. The detector can be a little sensitive about the position it’s held in, so if the led doesn’t light up, try moving the detector around a little while keeping the copper strip close to the wire warning experiment and have fun, but never ever touch the copper strip.

To a bare wire that has live voltage, it’s also fun to see how it detects static electricity. Try quickly rubbing your hand across some carpet several times, then hold your hand near the copper strip. The led should light up brightly from the static charge, buildup be sure to visit the project page and share your build. It’S also a great place to get any help needed to build this project. You .