Hi, this is Wayne again with a topic “How Do PCBs Work?”.

So you just bought a shiny, new motherboard and after you’re done looming and eyeing over the heatsinks that say xtreme gamer that are designed to look like a battle ax or whatever. You might have noticed all those tiny traces on the board that connect all of your ports, headers and sockets together, and actually make the board light up and function correctly and, although they’re not particularly exciting traces on printed circuit boards or PCBs, have basically made all of Modern electronics possible, in fact before they became widespread in the latter half of the 20th century, connecting every electrical component inside of an appliance looked a little something like this: a huge mass of individual wires. This is actually a look inside of a TV from 1948 and you imagine trying to build a computer or even buy a flat panel TV if you had to deal with that. Fortunately, the idea of embedding wires in a flat piece of fiberglass really took off as the years went by making it possible to fit a PC in a backpack instead of a giant cabinet. But how exactly then, do they pack so many important connections in such a small space? The process is actually somewhat similar to how CPUs are manufactured, which you can learn more about in this article.

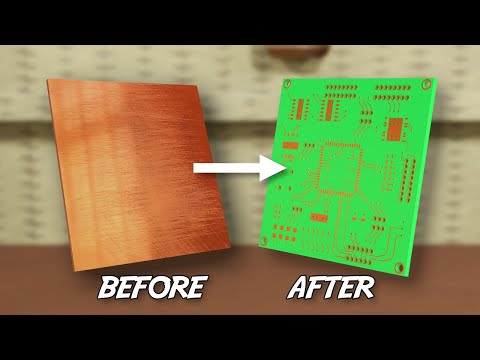

I’Ll, be it add a bit of a less complicated scale. Slices of fiberglass are stacked together and treated with a resin makes them stick to each other. To make one solid slab, then layers of copper are applied to both sides and coat it in a chemical called photoresist. After this, a pattern that matches up exactly to the traces that are supposed to go on the board is placed on top. Then the whole thing is exposed to UV light.

The board is then washed which well washes away the uncovered areas leaving tracks of copper. These tracks serve as a base for how the PCB will ultimately look after a couple of more steps, including catching additional, copper and more washing, but keep in mind that this process is often done in layers, which is why it’s a terrible idea to try and drill. Through your motherboard, if you’re having trouble mounting a cooler to it, the Internet has more than a few tales of people that tried to do this, only to find out that their board didn’t work at all afterwards, because they drilled in the middle of traces that were Visible from the outside, but went right through ones that were inside of it, but that isn’t to say that boards don’t get drilled at all during manufacturing at the factory boards, not only get mounting holes drilled through them for whatever form factor they happen to fit in.

But they also get small holes to accommodate connections for small electrical components like chips, capacitors and resistors, as well as tiny interconnects between the different layers of copper traces. So, after things like PCI Express slots, heat sinks and CPU sockets are mounted or soldered to the board. It’S basically finished, but since a PCB is just a collection of electrical connections on some kind of a substrate, you don’t actually need any fancy manufacturing processes to make a simple one.

In fact, you can even buy markers that will dispense electrically conductive ink onto special paper. So you can literally draw your own working PCB, pretty cool, but given the inherent complexity in manufacturing, something like an ATX motherboard, I wouldn’t count on being able to make your own one of those and maybe stick to you know making LED art that you can stick To your refrigerator speaking of art, you can stick to your refrigerator with a lynda.com membership. You can take that art, be it photography, video editing, creating fantastic PowerPoint presentations and take it to the next level.

Whether you’re looking to improve your skills at your hobby or get a brand new career lynda.com can help you they’ve got thousands of video courses that you can stream on demand that are taught by top expert. Two are passionate about teaching and they’ve. Got lots of great techy features too, like being able to browse transcripts scrub through the actual transcript and skip to that point in the video for any relevant diagrams or visuals. They’Ve got the ability to download the courses onto your iOS or Android device and watch them on the go without using your data, and you can even create and save playlists of courses that you want to watch to customize your Learning Path or to share with friends. Colleagues and team members so visit linda.com we’ve got it linked in the video description and get a free trial. Today, you’ll get 10 days to find out whether lynda.com is right for you and after that plans start at a flat rate of just 25 bucks per month.

So check it out, that’s lynda.com, slash tech quickie thanks for watching guys, if you liked the video like it, if you disliked it dislike it, if you want to check out other channels, do that if you want to comment with a video suggestion, do that and if You want to subscribe. Well, then you’re a cool person go ahead and do that .