Hi, this is Wayne again with a topic “Hot Wire Ice Cutter”.

Have you ever wanted to sculpt something out of ice this week, I’m going to show you how to make a hot wire ice cutter. The basic design is the same as any other hot wire cutter. Electricity is used to heat a piece of nichrome wire, and this can be used to precisely melt a line through whatever material you’re working with to make it easier to work with large blocks of ice. I decided to make this cutter handheld instead of mounting it to a table to build the cutter. You’Ll need some nichrome wire three feet of 1×2 lumber.

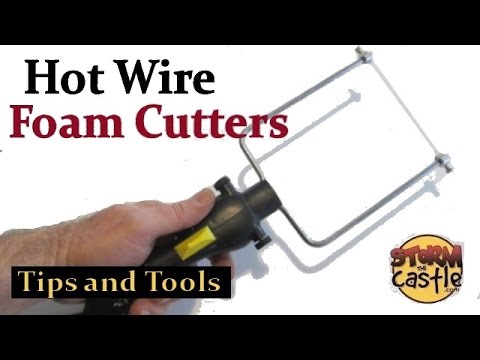

Four quarter inch bolts, ten quarter, inch, nuts, eight quarter-inch washers, some rubber bands and a large DC power supply start by cutting the 1×2 lumber into three pieces that are each about a foot. Long on one piece make a mark three quarters of an inch from each end. This will be the center board on the other two pieces, make one mark. That’S three quarters of an inch from the left side and a second mark. That’S six and three quarters of an inch from the left side. These will be the side boards drill a quarter inch hole in each of these locations to assemble the frame insert the bolt and washer through the holes on the center board then slide on the two side boards and add a washer and nut onto each one to Hold them in place now you need to attach the wire mounting bolts, add two nuts and a washer to the two remaining bolts fit these through the holes on the ends of the two side.

Boards, then add a washer and another two nuts onto the other side. These bolts are where we’ll attach the nichrome wire and the wires from the power supply. Now you need to select a DC power supply. I highly recommend using a power supply with output wires that can be easily separated without exposing either wire. When comparing power supplies, you need to do a little math to determine how hot each power supply will make the wire here’s a quick example start by checking the label to see the rated output voltage and current. In this case it was 12 volts and 2 amps.

This is the output that the power supply is designed to have so we want to duplicate this first calculate the power rating of the power supply by multiplying the output voltage by the output. Current then find the design load resistance by dividing the output voltage by the current now divide the design load resistance by the resistance of your wire to determine how long the wire needs to be. Lastly, divide wattage rating by the length of the wire to determine how many watts per foot will heat the wire. This value won’t tell you exactly what temperature the wire will reach, because that depends on how and where you’re using the cutter.

But it will give you a good way to compare the relative outputs of different power supplies once you’ve selected a power supply you’re, ready to hook up the cutting wire. Take the length of wire that you just calculated and add 2 inches to it. Cut off this length of wire on each end make a loop and twist the wire against itself to make a strong connection hook. The loops over the ends of the two mounting bolts on the other side of the bolts connect the output wires from the power supply to help keep the wires from moving around.

I taped them to the sides of the frame to make sure that the cutting wire will always be held tight. I added rubber bands to the opposite end of the side boards once everything is assembled. You’Re, ready to start working before plugging in the power supply, keep in mind that the wire will get extremely hot, so be very careful when using it always hold the cutter with both hands and unplug it whenever you’re not actively using it, get a large chunk of Ice or a stack of smaller pieces of ice and set them up on a dish in the middle of your workspace as soon as you plug in the power supply, the wire will immediately start to heat up, move the wires slowly through the ice to cut it. The ice will have a tendency to refreeze after the wire passes through it to deal with this. You can move the wire back and forth as you go. It also helps if you cut off smaller pieces at a time.

You can also use the hot wire ice cutter to shape snow and ice outdoors, but keep in mind that the outside temperature will affect how well the wire can cut. If it’s freezing outside the wire will lose a lot of heat to the surrounding air and it won’t be able to cut as fast well that’s how to make a hot wire ice cutter thanks for watching and check back next week for more DIY hacks and how To’S, you .